In the world of precision manufacturing, a large CNC machine has become an indispensable tool for industries that require highly accurate and complex parts. These machines, powered by computer numerical control (CNC) technology, are designed to automate the process of cutting, shaping, and engraving materials with remarkable precision. Whether you’re working with metals, wood, plastics, or composites, a large CNC machine can significantly enhance the production process.

Large CNC machines are equipped with advanced features that enable them to carry out multiple tasks, such as drilling, milling, and turning, all with minimal human intervention. The main advantage of using a large CNC machine is the ability to produce consistent, high-quality parts in large quantities, which is essential for industries like aerospace, automotive, and construction.

Key Features of a Large CNC Machine

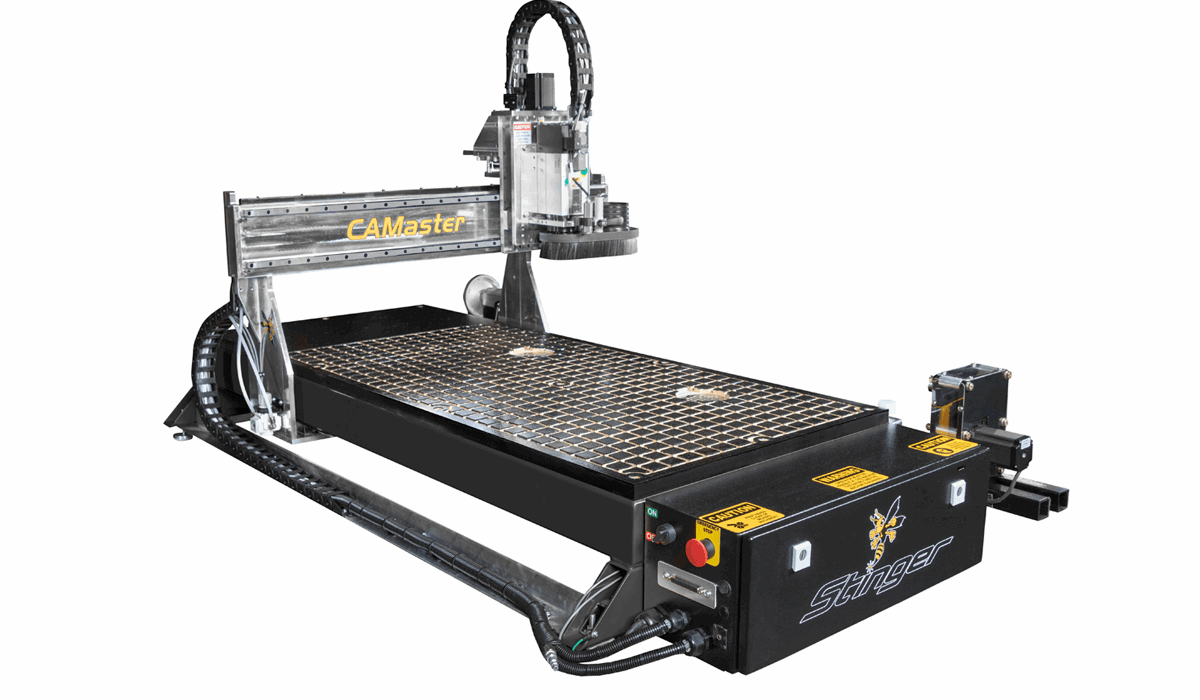

One of the standout features of a large CNC machine is its size. These machines typically have expansive worktables, such as those found in a 5×10 CNC router, allowing manufacturers to work on larger components or process multiple pieces at once. The precision and automation that come with these machines make them ideal for industries that require high volumes of production with tight tolerances.

The cutting tools used in a large CNC machine are also highly advanced. These tools can be customized to suit specific tasks, allowing manufacturers to switch between different operations quickly and efficiently. Some large CNC machines come equipped with automatic tool changers, further streamlining the production process.

Another important feature of these machines is their ability to handle a variety of materials. Whether it’s wood, metal, acrylic, or even foam, large CNC machines can cut, carve, or mill with exceptional accuracy, offering versatility for a range of industries.

The 5×10 CNC Router: A Game Changer in Large-Scale Production

Among the many types of large CNC machines available, the 5×10 CNC router has gained considerable popularity due to its ideal balance of size and capability. With a 5×10 configuration, these routers offer an impressive 5 feet by 10 feet working area, making them suitable for processing larger sheets or panels. This size makes the 5×10 CNC router a perfect solution for industries such as furniture manufacturing, cabinetry, and sign making.

A 5×10 CNC router’s ability to handle large panels and pieces of material while maintaining accuracy is a significant advantage. The precision cutting and engraving features allow manufacturers to create detailed designs and intricate patterns, often requiring very little post-processing.

Applications of Large CNC Machines

The potential applications of a large CNC machine are vast and varied. From industrial sectors like aerospace to creative fields like custom woodworking, large CNC machines can be used to create prototypes, tools, parts, and entire assemblies. In particular, the 5×10 CNC router has become an essential tool in industries requiring high-volume production of precision components.

In the automotive industry, large CNC machines are used to create engine parts, chassis components, and other mechanical assemblies. The precision offered by these machines ensures that each part fits seamlessly, reducing the need for manual adjustments or rework.

Similarly, in the construction industry, large CNC machines are utilized to cut and shape building materials, including metal panels and timber, for a variety of structural and aesthetic applications.

The Future of Large CNC Machines

As manufacturing technologies continue to evolve, the capabilities of large CNC machines are also advancing. With the integration of artificial intelligence, machine learning, and improved automation, these machines are becoming even more efficient and accurate. The future holds promising advancements in materials handling, tooling, and design capabilities, which will make large CNC machines even more valuable to industries across the board.

Conclusion

Large CNC machines, particularly the 5×10 CNC router, are at the forefront of modern manufacturing. Their ability to deliver precise, consistent results across a wide range of materials makes them a key asset in industries that require high-volume, high-accuracy production. As technology continues to improve, we can expect these machines to become even more sophisticated, pushing the boundaries of what is possible in the world of precision manufacturing. Whether for prototyping or large-scale production, a large CNC machine is a critical tool for achieving top-quality results in the shortest amount of time.